A pressure transducer is an electro-mechanical device that converts the mechanical force of pressure into a proportional analog electric signal. This analog electric signal in conjunction with a recording or read-out device serves as a measure of the applied pressure.

Taber Industries designs and manufactures bonded foil strain gage-based pressure transducers.

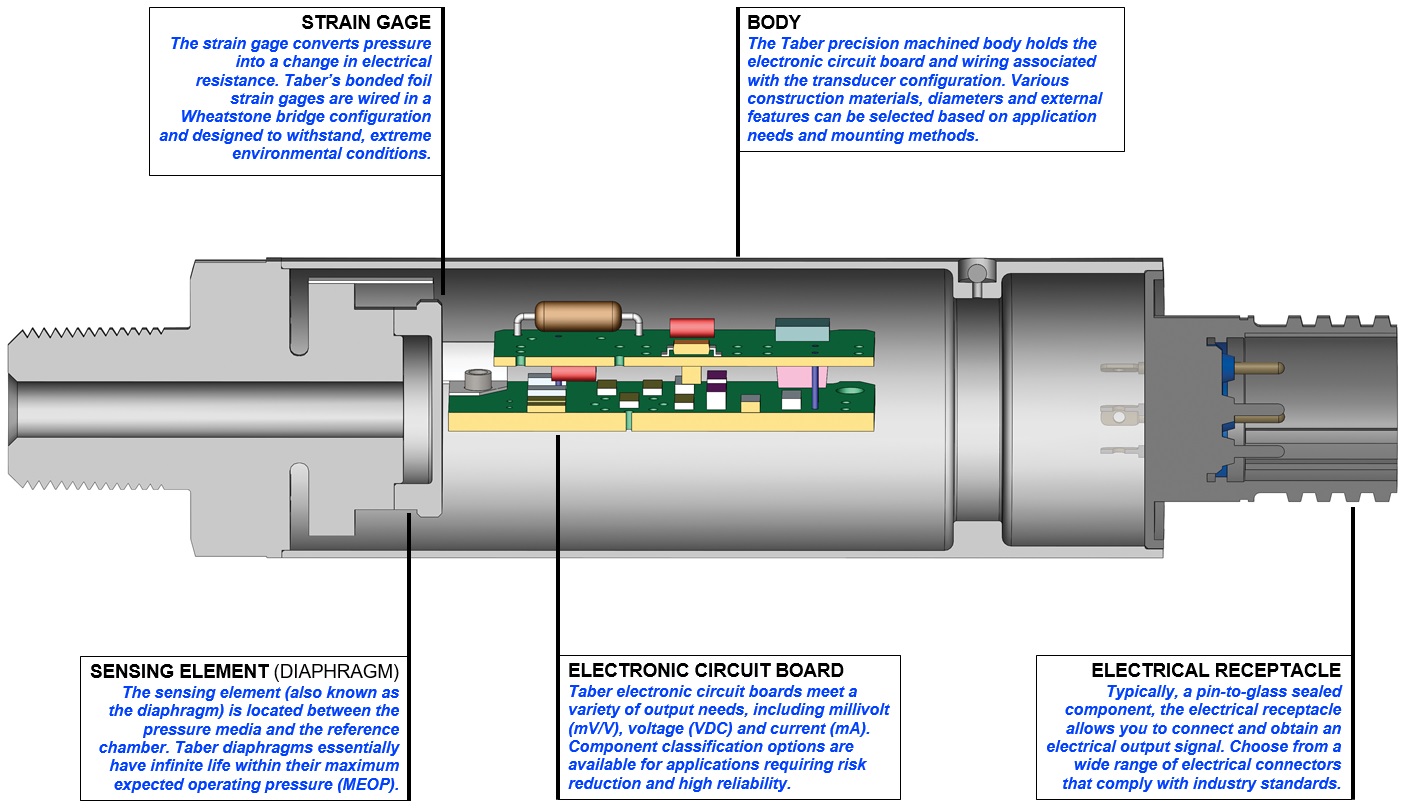

A typical transducer assembly consists of a pressure cap, sensing element, body, electronic circuit board, and an electrical receptacle.

The sensing element is constructed by welding a stainless steel disc or diaphragm to a stainless steel pressure cap. It is exposed on the pressure cap side to the fluid whose pressure is being measured. The other side of the diaphragm typically faces a hermetically sealed vacuum chamber or the evacuated body chamber that houses the electronic circuit boards. An array of four metal foil strain gages is carefully bonded onto this side of the diaphragm and wired into a Wheatstone bridge configuration. Initially, the Wheatstone bridge is balanced so that the electrical output from the bridge is zero when the input voltage is applied.

When pressure is applied, it causes a deflection of the diaphragm which introduces strain to the gages. This strain will produce an electrical resistance change in the gages proportional to the pressure which then causes the Wheatstone bridge to become unbalanced resulting in an electric output. This electric output which is a measure of the applied pressure may be read using appropriate instrumentation.

If you have a question regarding Taber Transducer products, please complete the following form and we will contact you as soon as possible.

US & Canada