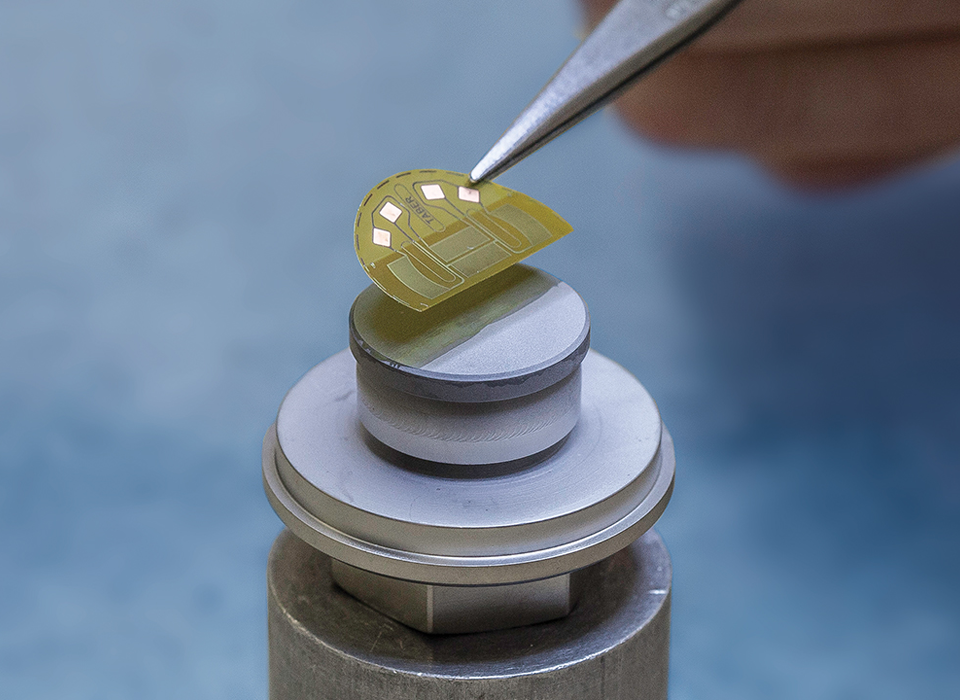

Taber University is Taber Industries’ guide to all things pressure transducer related. For even more information regarding our pressure transducers, please visit the Pressure Transducers Models page or follow the links within each subject below to learn more! Producing a precision Taber Transducer requires an array of sophisticated production equipment, skilled manufacturing technicians, and detailed engineering support. In addition, computer-operated test consoles are utilized to check and calibrate each individual transducer to ensure its reliability and accuracy in the critical applications for which it is intended. Testing is an integral part of the manufacturing process and is used to confirm the transducer will perform as expected within the working environment (e.g. shock and vibration, temperature extremes, etc.).

• AS9100 Certified Company • IPC J-STD-001SCertified Technicians • Gas Tungsten Arc Welding per AWS D17.1 • Class 100 Laminar Flow Bonding Booths • Temperature & Humidity Controlled Solder Stations • ESD Control Program • Stereoscopic Microscope Stations • 200x Video Microscope • NIST-Traceable Calibrated equipment • Full Service Machine Shop

Select a subject below to learn more about Taber Transducers! Feel free to contact us if you are looking for additional information.

Taber Industries designs and manufacturers bonded foil strain gage based pressure transducers. This section describes the technology behind Taber’s transducers.

Taber Industries manufactures several types of transducers for many different industries. Read more about those types and industries here.

An electrical input, called the excitation voltage, is required to operate a pressure transducer. This DC excitation produces a voltage or current output depending on the transducer configuration. Find out more about what inputs/outputs Taber offers here.

Taber pressure transducers can be configured to measure pressure with respect to all the common pressure references such as PSIG, PSIV, PSIS, PSIA, and PSID. Consult this section to understand what pressure reference is required for your application.

Pressure and temperature are two main criteria when specifying a pressure transducer. Both have unique sets of units from several standards. Learn more about those here.

Transducers are defined using a number of different terms. Learn more about these terms and how they are used here.

Several factors play into the choice of circuits in a transducer such as response time, cost, temperature, and noise. Read more about these factors and more here.

Taber transducers are often used in extreme temperatures or operate in a range of temperatures. Transducers are designed to minimize the influence of temperature and are compensated by electrically adjusting the output circuit. Reference this page for more information about temperature compensation.

Taber transducers have a long history of providing accurate measurements in even the harshest conditions. Learn more about what is behind the accuracy and how it is expressed.

If you have a question regarding Taber Transducer products, please complete the following form and we will contact you as soon as possible.

US & Canada